The Genesis of a Stronger Connection

This is our independent website, you can check out our products.https://pjcases.com

At our core, we are problem solvers. For years, we saw the same frustration cycling through our team and our customers: the inevitable fraying, snapping, and failure of standard charging cables. A device a user relies on daily deserves a connection that is just as dependable. This shared experience sparked a mission within our design lab to create a solution that was not only durable but also elegant and efficient. We went back to the drawing board, determined to engineer a braided data cable that would redefine expectations and become a permanent, reliable accessory in our customers’ lives, ending the cycle of constant replacement.

Designing for Durability and Performance

Our journey began with material science. We knew that the outer shell was the first line of defense, so we moved away from standard plastics and rubbers. Instead, we chose a high-density, multi-filament nylon for our weave. This material is renowned for its incredible tensile strength and resistance to abrasion, but the real magic is in the braiding technique itself. The tight interlocking weave doesn’t just protect the delicate wires within; it prevents tangling and resists the wear and tear from bending and coiling. Inside this protective shell, we focused on performance. To create a true fast charging braided cable, we engineered the internal architecture with thicker, low-resistance copper wires and enhanced shielding. This not only ensures the fastest possible charging speeds your device can handle but also guarantees safe and stable data transfer.

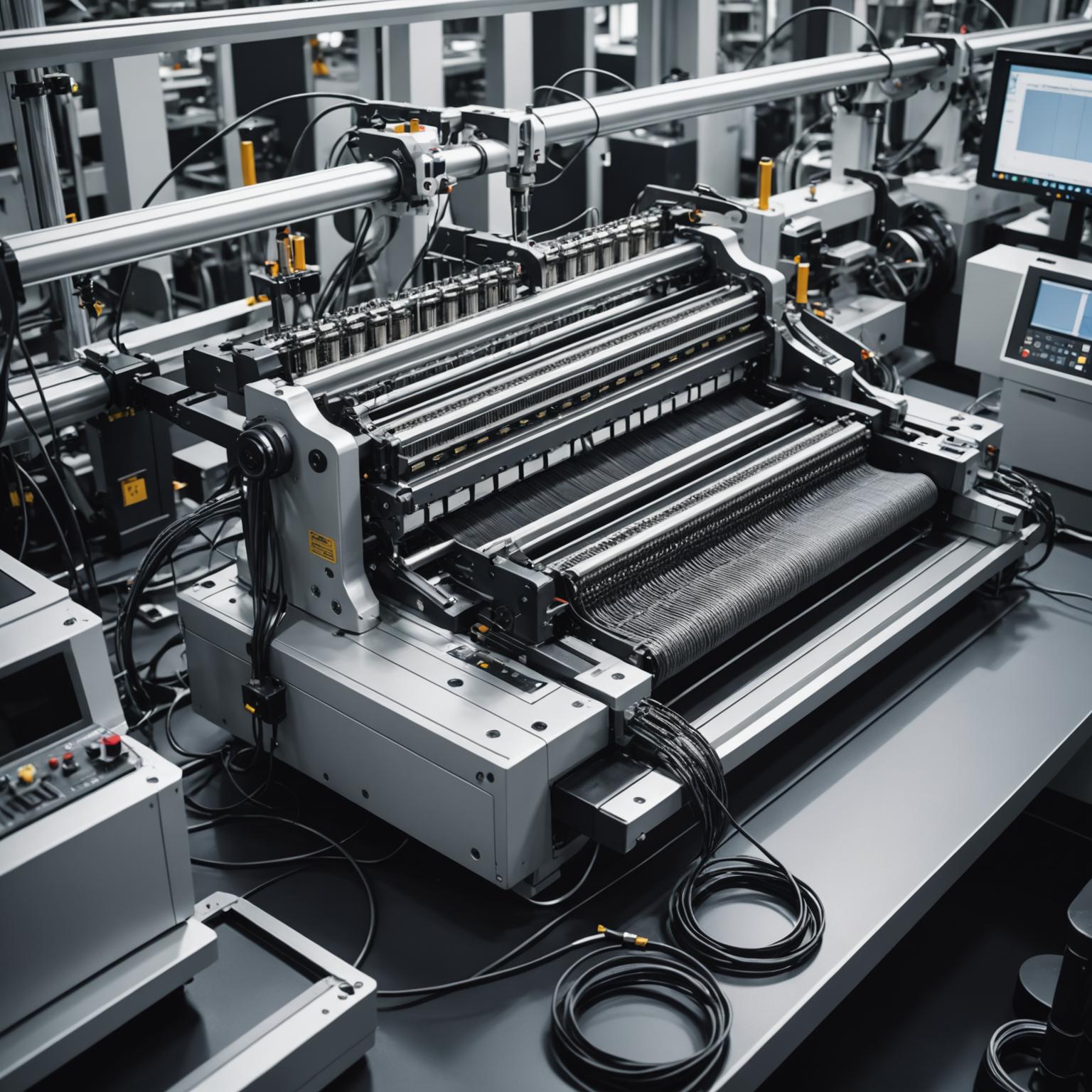

The Craft Behind the Cable

Step onto our production floor, and you won’t just see machines; you’ll see a synergy of precision engineering and human oversight. Each braided USB cable begins its life as spools of fine nylon threads, which are fed into a specialized braiding machine. This equipment, calibrated to our exact specifications, weaves the threads into the tight, durable sheath that gives our cables their signature look and feel. The process is hypnotic, a dance of bobbins creating a perfect, consistent pattern. We also reinforced the most common point of failure: the neck of the connector. By using a flexible, elongated strain relief collar, we distribute stress away from the delicate connection point, drastically increasing the cable’s lifespan. It’s a small detail, but it’s one that makes a world of difference.

Tested to Extremes: Our Promise of Reliability

Before any cable is packaged, it faces a gauntlet of quality control tests that simulate years of real-world use. Every design is subjected to over 10,000 bend tests, where a machine repeatedly flexes the cable at a 180-degree angle to ensure the connections remain solid. We perform pull tests to verify the strength of the connectors and the braiding, and we run continuous charging and data transfer cycles to confirm unwavering performance. Only after a braided data cable passes every single one of these rigorous checks does it earn our seal of approval. This meticulous process isn’t just about quality control; it’s about fulfilling our promise to you: a connection you can count on, day in and day out.