In the ever-evolving landscape of mobile accessories, the spotlight often shines on the sleek finishes, vibrant colors, and robust functionality of the products we love. Today, we take a behind-the-scenes look at the extraordinary process behind the manufacturing of a ‘phone case,’ a product many of us use daily but seldom think about in depth.

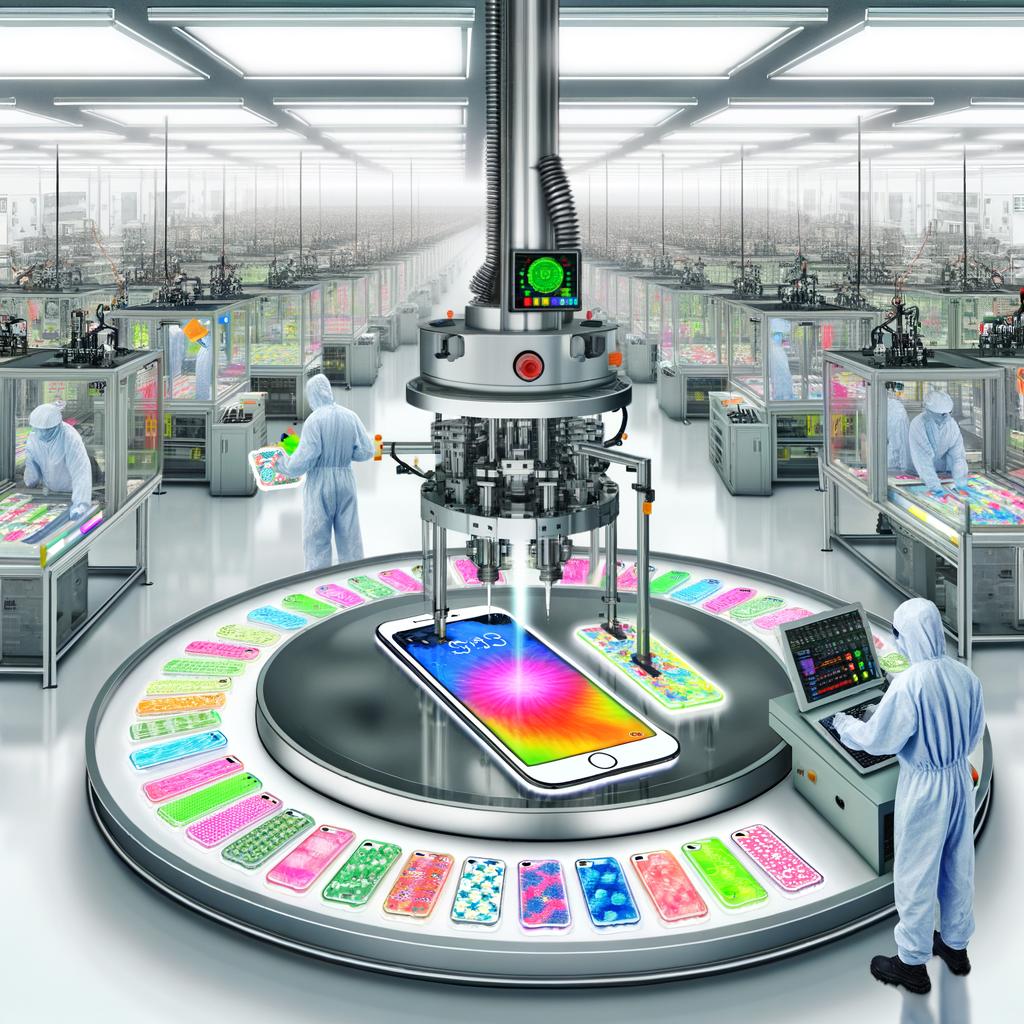

Guangzhou Pinjun Electronics Co., Ltd., a leader in the industry with over 15 years of experience, epitomizes innovation and dedication in phone case production. Operating out of a massive 15,000 square meter facility, their advanced manufacturing process begins with state-of-the-art equipment. These cutting-edge machines form the backbone of their production line, designed to handle high-volume manufacturing with unparalleled precision.

Their highly skilled workforce meticulously oversees every step of the process. With over 200 workers and 30 sales teams, the company ensures that each phone case meets stringent quality standards. The expertise and unwavering attention to detail of these operators are critical, as they navigate and manage sophisticated machinery to craft each case to perfection.

The phone cases produced by Guangzhou Pinjun are a marvel of both functionality and aesthetics. Customers are presented with a wide array of vibrant color options, ranging from elegant black and sophisticated blue to eye-catching pink and refreshing green. Additionally, the diversity in design options—from sleek, smooth finishes to robust, textured variants—ensures that there is a phone cover to meet everyone’s taste and functional needs. This commitment to aesthetic variety without compromising on durability speaks volumes about the company’s dedication to customer satisfaction.

A standout feature of their production process is the exceptional quality control implemented at every stage. Each phone case undergoes rigorous inspection to ensure it covers all aspects of durability, aesthetics, and functionality. This meticulous quality assurance guarantees that the products not only look fantastic but also provide superior protection for smartphones—meeting the highest expectations of their discerning clients.

The production process is further elevated by the introduction of their latest innovation: the Automated Precision Injection Molding System. This high-tech assembly line, equipped with intuitive touch screen interfaces and highly advanced injection molding machines, allows for superior product quality and consistency. The system’s integration of advanced networking technology ensures seamless communication among team members via devices such as smartphones and laptops, enhancing efficiency and responsiveness to production needs.

Guangzhou Pinjun’s user-centric system design includes robust user management software that tracks performance metrics in real-time, an asset that managers utilize to maintain operational efficiency. This integrated approach not only maximizes productivity but also adheres to strict quality control, embodying the future of manufacturing where technology and human capability synergize flawlessly.

In conclusion, the essence of Guangzhou Pinjun Electronics Co., Ltd.’s success lies in their ability to merge cutting-edge technology with exceptional craftsmanship. Their phone cases represent more than just protection for our devices; they are a testament to advanced manufacturing processes and dedicated human effort. As they continue to set the industry standard, customers worldwide can rest assured they are receiving products that are as finely crafted as they are functional.